Your Trusted DFW Replacement Company

SunSmart Replacement

Window Company of Fort Worth

Welcome to SunSmart Windows and Doors of Fort Worth, your premier choice for enhancing your homes windows and doors. With a commitment to quality and precision, our expertly crafted windows bring comfort, style, and efficiency to your living spaces. Experience unparalleled service and the beauty of functionality with our innovative designs tailored for your home.

Welcome to SunSmart Windows and Doors of Fort Worth, your premier choice for enhancing your homes windows and doors. With a commitment to quality and precision, our expertly crafted windows bring comfort, style, and efficiency to your living spaces.

Small Call to Action Headline

Get To Know Us!

Our Story

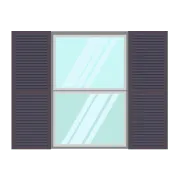

SunSmart Windows & Doors, established in 2013 and based in Fort Worth, Texas, specializes in selling and installing custom windows and doors for homeowners and contractors across Dallas and beyond. As a locally owned leader in the industry, we offer a wide range of products from various suppliers at different price points to meet your unique needs.

SunSmart Windows & Doors, established in 2013 and based in Fort Worth, Texas, specializes in selling and installing custom windows and doors for homeowners and contractors across North Texas and beyond. As a locally owned leader in the industry, we offer a wide range of products from various suppliers at different price points to meet your unique needs.

Our Services

At SunSmart Windows and Doors, we specialize in the design, sale, and installation of high-quality custom windows and doors. Our offerings range from innovative Dallas residential window installations to luxurious door enhancements, ensuring each project meets our rigorous standards for energy efficiency and style. Whether you're updating your home or constructing a new one, our expert team is equipped to bring your vision to life with precision and craftsmanship.

At SunSmart Windows and Doors, we specialize in the design, sale, and installation of high-quality custom windows and doors. Our offerings range from innovative residential window installations to luxurious door enhancements, ensuring each project meets our rigorous standards for energy efficiency and style.

Meet The Owners

SunSmart Windows and Doors is owned by Lindsey and Scott Stewart, and every aspect of the business is run by the Stewart family. Whenever you interact with SunSmart, you’re dealing with a representative who’s personally invested in finding the best window and door options for your home. Lindsey and Scott also own and operate Lone Star Blinds and Shutters, so please let us know if you need help with window coverings as well.

SunSmart Windows and Doors is owned by Lindsey and Scott Stewart, and every aspect of the business is run by the Stewart family. Whenever you interact with SunSmart, you’re dealing with a representative who’s personally invested in finding the best window and door options for your home. Lindsey and Scott also own and operate Lone Star Blinds and Shutters, so please let us know if you need help with window coverings as well.

What The Neighbors Say About Us

Types of Windows

Single-Hung

A single-hung window has a lower sash that moves upward while the upper panel remains static.

Double-Hung

Double-hung windows allow movement of both upper and lower sashes for more airflow.

Casement

Casement windows are hinged at the side, allowing them to open outward for full ventilation.

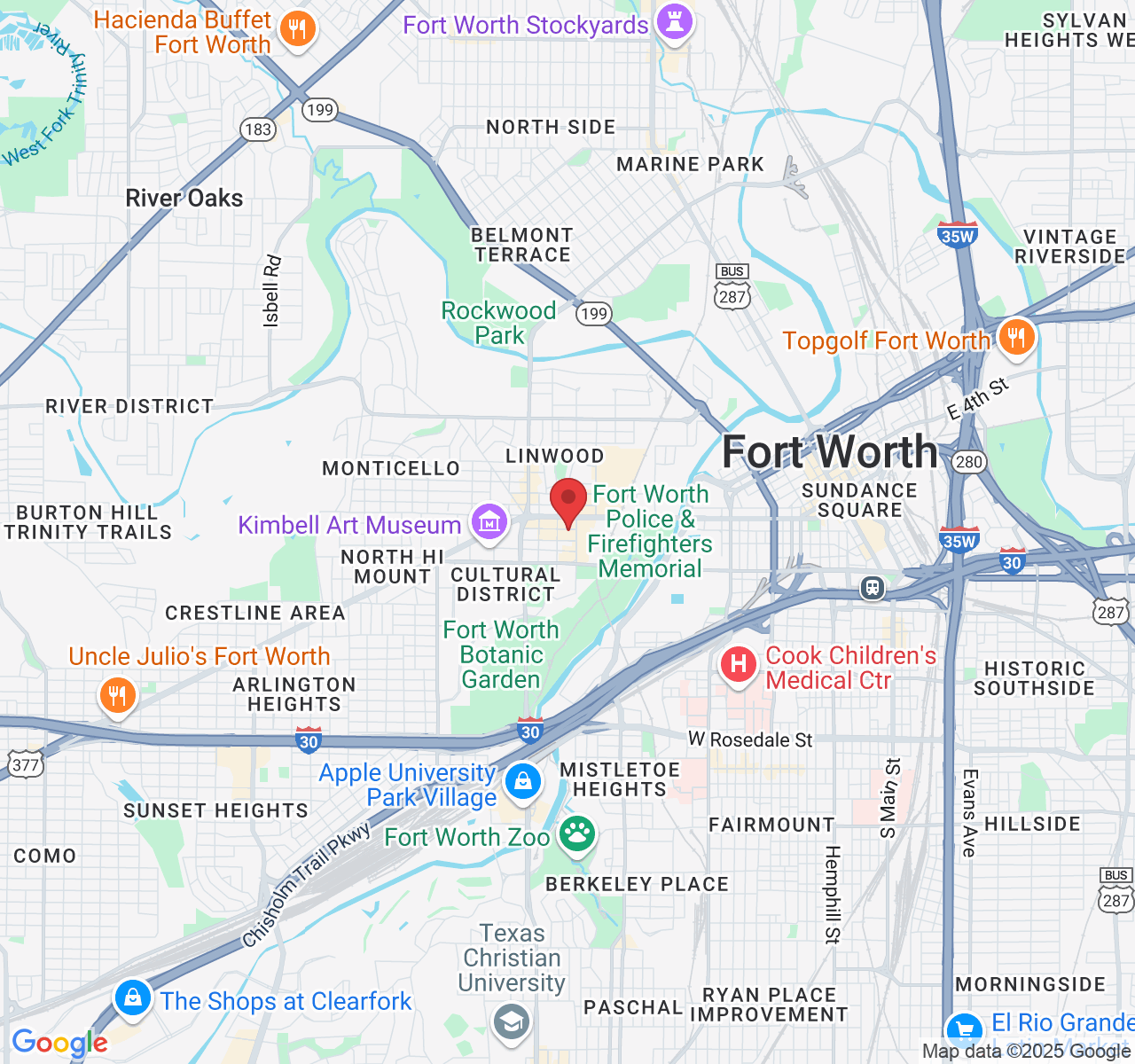

Bay-Windows

Bay windows are made of three glass panels that extend from an exterior wall, creating extra interior space.

Bow-Windows

Bow windows consist of five or more glass panels, extending outward to enhance space and architectural appeal.

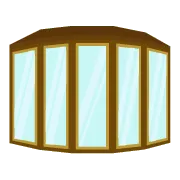

Sliding

Sliding windows feature a large glass area and slim frames, opening horizontally along a track for convenience.

Storm

Storm windows provide extra insulation and protection, effectively shielding against severe weather.

Garden

Garden windows, in various sizes and styles, are ideal for growing a wide range of indoor plants, enhancing any living space.

Transom

Transom windows are perfect for adding extra light above doors or existing windows, brightening interiors effectively.

Check Out Our Five Star Work

Our team of master installers ensures that every window and door is fitted with precision. Their meticulous approach guarantees perfect alignment and functionality, enhancing the overall performance and aesthetics of your home.

We tailor every project to meet your specific needs. From the initial design consultation to the final touches, our solutions are designed to reflect your style and improve your home’s energy efficiency.

Our commitment to quality is evident in every project we undertake. We use only the best materials and techniques, ensuring that every installation not only meets but exceeds industry standards.

FAQS

What is a Fort Worth Replacement Window?

A replacement window is designed to fit into the existing frame of an old window in your home. This allows for an upgrade in window quality, performance, and aesthetics without the need for altering the surrounding wall structure. Replacement windows are a cost-effective way to enhance the functionality and energy efficiency of your Dallas home.

Why should I want get a window replacement service for my home?

Replacing builder-grade windows and doors is beneficial because these are often the basic models installed to keep construction costs down. Upgrading to higher-quality windows and doors improves energy efficiency, enhances security, reduces noise, and increases the aesthetic appeal of your Dallas home. Higher-quality materials used in better windows and doors can also offer greater durability and better functionality, providing long-term savings and comfort.

If I am going to replace my windows and doors, how do I know what product or company to use?

Proper installation is key to ensuring your windows and doors perform effectively and last long. At SunSmart, our experienced professionals ensure every installation is done meticulously to uphold our high standards.

How important is the installation?

Proper installation is key to ensuring your windows and doors perform effectively and last long. At SunSmart, our experienced professionals ensure every installation is done meticulously to uphold our high standards.

Will I get my money back through energy savings?

Modern, energy-efficient windows and doors can significantly reduce your heating and cooling costs, potentially offsetting the initial investment over time through lower energy bills.

Will I get my money back when I sell my home?

Investing in high-quality windows and doors can increase your Dallas home’s value, often allowing you to recoup a significant portion of your investment upon resale, thanks to their appeal to potential buyers.

Contact Us

Better yet, see us in person!

We love our customers, so feel free to visit during normal business hours.

Sunsmart Windows and Doors of Forth Worth, TX

2833 Crockett St #144

Fort Worth, Tx 76107

817-601-7035

Fun Stuff

With a commitment to quality and precision, our expertly crafted solutions bring comfort, style, and efficiency to your living spaces. Experience unparalleled service and the beauty of functionality with our innovative designs tailored for the contemporary homeowner. Discover the difference with SunSmart, where your home's potential is our passion.

SiteMap

Services

Follow Us!